Operation

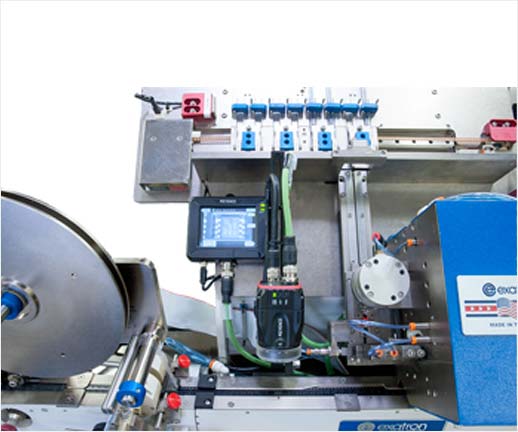

- Sensor quickly identifies Pin1 corner - alerts operator to improperly rotated, upside down, and damaged parts

- Intuitive touch - screen interface - easy to setup sensor and edit inspections

- Sensor integrates seamlessly with Exatron PLC, no additional PC required

Features

- Simple setup, easy to use

- Thermal or PSA sealing

- 8 tube "octo-loader" automatic input feeder

- Snap on input tube tooling with quick change input track kits

- Unique tape guide block guarantees proper alignment of carrier and cover tape

- no micro-adjustments needed -In pocket vision - Pin1, empty/out of pocket, upside down (see reverse)

- Independent seal head pressure and temperature control

- Micro terminal for current status, setup, and diagnostics

- Stand-alone operation, no PC required

NOTE: the specifications and general features are the same as those of the Model 1010 taper.

Options

Optional equipment is the same as that available for the Model 1050, including in-line laser markers, labelling equipment, vision systems, etc.