Exatron offers integrated vision upgrades for a wide range of systems and applications.

Precision BGA, QFN, and leaded 3D measurement.

Precision BGA, QFN, and leaded 3D measurement.

- On the fly inspections.

- Flexible and intuitive user interface.

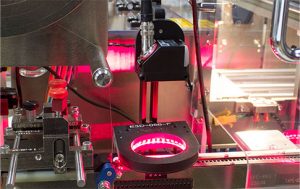

Economical 2D Inspection.

Economical 2D Inspection.

- Custom illumination.

- Robotic control for precision handling.

Pattern verification and Optical Character Recognition

Pattern verification and Optical Character Recognition

- Latest technology.

- Custom software solutions.

Smart Mark® laser marker vision upgrade

Smart Mark® laser marker vision upgrade

- Aligns new marks to existing marks on each individual device.

- Ensures precision marking.

Tape and reel inspection

- Pin1, orientation, upside down, and out of pocket status.

- Ensures no empty pockets or improperly seated devices before sealing.

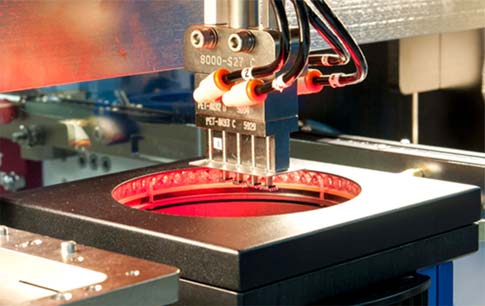

Camera-aided test/program socket alignment

- Quick and easy calibration.

- Seamless integration with Exatron software.

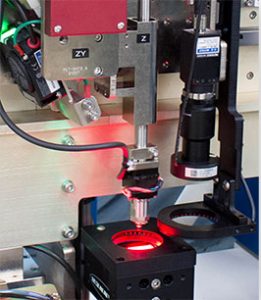

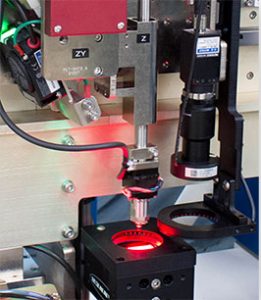

Robotic alignment

- Top inspection conducts gross alignment to ensure precise pickup.

- Bottom inspection identifies X,Y, angle position of device and pickup adjusts as needed.

- 360º rotating pickup head travels on X, Y, and Z axes.

- Handles devices as small as 0.8mm x 0.8mm

Random sort

- Top camera locates and reports position of devices matching size/type specifics scattered on the bulk tray.

- Pickup head picks specified devices and rotates as needed.

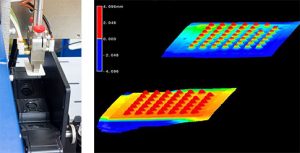

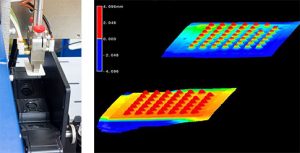

3D vision options

- Height measurement and extraction.

- X, Y, Z measurement less than 24μm (1μm repeatability).

- Real-time reference plane correction.