OPTIONS:

- Full and mini changeover kits for additional device/tube sizes.

- Over 100 options available.

- For lead counts from 4-66 pins.

- Changeover is quick and easy. (10 minutes max.)

- No other handler accepts a wider variety of tubes and devices.

- RF test, multiple test sites, Hi Pot, and direct dock interfaces.

- Hot rail for testing to 125° C. (See Model 3080B.)

- Print and apply labeler.

- Laser marking.

- Bowl feed input/bucket output.

- Light pole, floor mount, and/or safety cover.

- Spare parts kit.

- On-site installation.

SPECIFICATIONS:

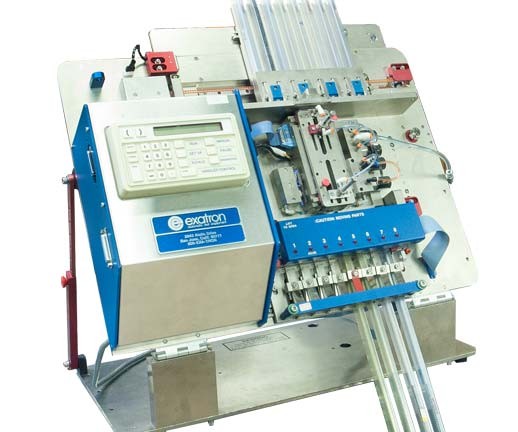

Size: 0.66m (26”) W x 0.5m (20”) D x 0.5m (20”) H (Table top model)

Weight: 15.8kg (35lbs)

Power Required: 100-240 VAC, 50/60Hz

Air Pressure Required: 5.5. bar (80psi), 1 CFM clean, dry air

OPERATION:

Blank/untested devices are loaded in tubes at the top of the handler then indexed to a test contact mechanism. Among the standard choices, the customer may select special SMD (Surface Mount Device) test sites which plunge the Device Under Test (DUT) up to 1.5 inches past the back of the handler to a load board. Programming and testing takes place here, using any of several types of programmers and testers. The devices are sorted by "Pass" and "Fail" categories after each test. After testing, failed devices are sorted into reject tubes. Devices which pass the test stage are sorted to the output tubes for retrieval by the operator.

The Model 3000B handler operation is constantly monitored by its STD Bus CPU. Once a device enters the handler, it is tracked by sensors as it passes through every step until it is positively placed in the correct output tube. If a device jam should occur, an appropriate error message will be displayed on the handler controller's front panel micro terminal. Most jams may be cleared by pressing the Run or Clear buttons on the front panel.

The handler may be operated in either of two modes: AUTO or MANUAL. MANUAL operation allows for Handler Diagnostics sequences to be run, Handler Set-Up changes to be entered, and mechanical adjustments to be made at the operator's convenience before, during, and after automatic Handler operation.

AUTO operation continuously cycles devices through the handler. The handler will stop when empty but re-start automatically when more devices are loaded. Each output tube may be filled to any pre-set amount, with individual counters keeping track of quantities in all outputs. When an output tube fills,the handler automatically begins to fill any other unfilled tube assigned to the sort signal received from the tester. When all output tubes are filled, the handler will stop and a message will be displayed, such as "ALL OUTPUTS FULL." The tube counter is automatically reset by removing the full tube and re-inserting an empty tube. The handler will not cycle devices to outputs which have no tubes or which are full. Additionally, a continuous subtotal count in maintained for each output, up to a total of 999,999 devices.

Sorting is accomplished by use of a stepper motor and a solenoid released shuttle. Dual positive binning sensors keep track of the shuttle's position at all times. In the event of a sorting problem, a message will be displayed on the handler's front panel, and the devices will not be binned until the problem is corrected.